Importance of surface preparation for waterproofing:

Introduction to surface preparation:

Waterproofing is a crucial component of any building project, whether it’s a commercial or residential property. While the focus is often on selecting the right waterproofing materials, the importance of proper surface preparation is often overlooked. However, this is a critical step that can determine the success or failure of the waterproofing project. In this blog post, we’ll explore why surface preparation is so important, the various methods, machines and materials involved in it, and provide step-by-step instructions for achieving the best results.

Table of Contents

Importance of Surface Preparation:

Surface preparation is a crucial step in ensuring the success and longevity of any waterproofing project. Proper surface preparation ensures that the coating or membrane adheres well to the substrate, eliminating the risk of future delamination or other issues. Additionally, proper surface preparation helps to eliminate surface contaminants that can interfere with adhesion and contribute to coating or membrane failure over time. In this blog post, we will delve into the importance of surface preparation in waterproofing projects, discussing the benefits and methods of achieving the best results.

When it comes to waterproofing, surface preparation is one of the most critical factors for ensuring long-lasting, high-quality results. By taking the time to properly prepare the surface, you can increase the lifespan of the coating or membrane and enhance the overall quality of the project. Surface preparation can involve various techniques, including sanding, pressure washing, and chemical cleaning, depending on the type of substrate and the condition of the surface. In the following paragraphs, we will explore the different types of surface preparation methods, machines, and materials involved in the waterproofing process, as well as step-by-step instructions for achieving proper surface preparation.

Types of Surface Preparation

- Methods, Machines, and Materials Involved

- Cleaning Machines

- Pressure washers

- Pressure washers are a popular cleaning machine that is commonly used for surface preparation in waterproofing projects. These machines work by blasting water at high pressure to remove dirt, grime, and other surface contaminants, providing a clean surface for the waterproofing coating or membrane to adhere to. Pressure washers are particularly effective at removing stubborn stains and buildup, such as algae, moss, and oil, that can be difficult to remove using traditional cleaning methods.

- When using pressure washers for surface preparation, it is important to use the appropriate pressure setting and nozzle attachment for the specific surface being cleaned. Too much pressure can damage the surface, while too little pressure may not effectively remove all contaminants. Additionally, care should be taken to avoid using pressure washers on delicate surfaces, such as wood or soft metals, which can be easily damaged. Overall, pressure washers can be a valuable tool for achieving proper surface preparation and ensuring long-lasting waterproofing results.

- Pressure washers are a popular cleaning machine that is commonly used for surface preparation in waterproofing projects. These machines work by blasting water at high pressure to remove dirt, grime, and other surface contaminants, providing a clean surface for the waterproofing coating or membrane to adhere to. Pressure washers are particularly effective at removing stubborn stains and buildup, such as algae, moss, and oil, that can be difficult to remove using traditional cleaning methods.

- Sandblasters

- Sandblasters are powerful machines that use compressed air to shoot abrasive materials, such as sand, at high speeds to clean and prepare surfaces for coating or painting. Surface preparation is critical in ensuring that the coating or paint adheres properly to the substrate, and sandblasters are an effective way to achieve this.

- One of the benefits of using a sandblaster for surface preparation is its ability to remove even the toughest of surface contaminants, such as rust, corrosion, and old paint. By blasting away these contaminants with abrasive materials, the surface is left clean and free of any debris that could interfere with proper adhesion of the coating or paint. This can ultimately increase the lifespan of the coating or paint and enhance the overall quality of the project. However, it’s important to note that sandblasting should be used with caution on delicate surfaces, as it can be too abrasive and cause damage. Proper safety equipment and techniques should also be used to ensure the safety of the operator and those in the surrounding area.

- Sandblasters are powerful machines that use compressed air to shoot abrasive materials, such as sand, at high speeds to clean and prepare surfaces for coating or painting. Surface preparation is critical in ensuring that the coating or paint adheres properly to the substrate, and sandblasters are an effective way to achieve this.

- Chemical sprayers

- Chemical sprayers are a powerful tool for surface preparation in waterproofing projects. They work by atomizing chemical solutions into fine droplets that can be applied evenly across large surfaces. One of the main benefits of chemical sprayers is their ability to quickly and efficiently cover large areas, reducing the overall time and labor required for surface preparation. They can also be used to apply different types of chemical solutions, such as cleaning agents or etching solutions, to effectively remove contaminants and improve adhesion.

- However, it is important to use caution when working with chemical sprayers. The fine droplets they produce can be harmful if inhaled or come into contact with the skin or eyes. Proper safety equipment, including goggles, gloves, and respiratory protection, should be used at all times when operating a chemical sprayer. It is also important to carefully follow manufacturer instructions for the use and application of chemical solutions to ensure effective and safe surface preparation.

- Chemical sprayers are a powerful tool for surface preparation in waterproofing projects. They work by atomizing chemical solutions into fine droplets that can be applied evenly across large surfaces. One of the main benefits of chemical sprayers is their ability to quickly and efficiently cover large areas, reducing the overall time and labor required for surface preparation. They can also be used to apply different types of chemical solutions, such as cleaning agents or etching solutions, to effectively remove contaminants and improve adhesion.

- Pressure washers

- Mechanical Preparation Machines

- Scarifiers

- Mechanical preparation machines, such as scarifiers, are another effective option for surface preparation in waterproofing projects. These machines use rotating blades or cutters to remove old coatings, roughen surfaces, or level uneven areas. Scarifiers are particularly useful for preparing concrete surfaces, as they can quickly and effectively remove layers of old coatings or other contaminants.

- When using scarifiers or other mechanical preparation machines, it is important to consider the type and hardness of the substrate, as well as the type of blade or cutter being used. Different machines and tools may be required for different surfaces and conditions, and care should be taken to avoid damaging the substrate or creating excessive dust or debris. Overall, mechanical preparation machines can be a powerful tool in achieving proper surface preparation for successful waterproofing projects.

- Mechanical preparation machines, such as scarifiers, are another effective option for surface preparation in waterproofing projects. These machines use rotating blades or cutters to remove old coatings, roughen surfaces, or level uneven areas. Scarifiers are particularly useful for preparing concrete surfaces, as they can quickly and effectively remove layers of old coatings or other contaminants.

- Grinders

- When it comes to surface preparation for waterproofing, mechanical preparation machines such as grinders can play a key role in ensuring a smooth, clean surface. Grinders are used to remove surface coatings, adhesives, and other contaminants that can interfere with the adhesion of the waterproofing material. They can also be used to smooth out rough surfaces, level uneven surfaces, and prepare surfaces for the application of coatings or membranes.

- Grinders come in a variety of sizes and styles, ranging from handheld models to large, industrial-sized machines. The type of grinder chosen will depend on the size and complexity of the surface to be prepared, as well as the type of coating or membrane being applied. Proper use and maintenance of the grinder can help ensure the best results, and professional assistance may be required for larger or more complex projects.

- When it comes to surface preparation for waterproofing, mechanical preparation machines such as grinders can play a key role in ensuring a smooth, clean surface. Grinders are used to remove surface coatings, adhesives, and other contaminants that can interfere with the adhesion of the waterproofing material. They can also be used to smooth out rough surfaces, level uneven surfaces, and prepare surfaces for the application of coatings or membranes.

- Shot blasters

- Mechanical preparation machines like shot blasters are highly effective in surface preparation for waterproofing projects. Shot blasters use high-speed impellers to propel abrasive media at the surface, removing contaminants and roughening the surface for better adhesion of the coating or membrane. Shot blasters are particularly useful for preparing large surfaces like floors, walls, and ceilings.

- The use of shot blasters can significantly improve the overall quality and lifespan of waterproofing projects. Shot blasting ensures that the surface is properly cleaned and prepared for the waterproofing material, preventing premature failure or delamination due to poor adhesion. Additionally, shot blasting creates a rough surface profile, providing a mechanical bond for the waterproofing material that improves its strength and durability. With proper maintenance and use, shot blasters can be a valuable investment for any professional waterproofing service.

- Mechanical preparation machines like shot blasters are highly effective in surface preparation for waterproofing projects. Shot blasters use high-speed impellers to propel abrasive media at the surface, removing contaminants and roughening the surface for better adhesion of the coating or membrane. Shot blasters are particularly useful for preparing large surfaces like floors, walls, and ceilings.

- Scarifiers

- Repair Materials

- Crack fillers

- When it comes to waterproofing and protecting your surfaces, repairing cracks and gaps is essential. Before applying any waterproofing products, it is important to properly prepare the surface by filling in any cracks or gaps. This ensures that the waterproofing product adheres properly to the surface, providing maximum protection against water and moisture damage. Crack fillers are a type of repair material designed specifically for this purpose, offering a cost-effective and efficient way to address cracks and gaps in surfaces.

- There are many different types of crack fillers available, ranging from epoxy and polyurethane to latex and silicone. Each type of filler has its own unique properties and benefits, making it important to select the right product for your specific needs. Additionally, proper surface preparation is key to ensuring that the crack filler adheres properly and provides long-lasting protection. This may include cleaning and drying the surface, removing loose debris, and applying a primer if necessary. By taking the time to properly prepare and repair your surfaces, you can ensure that your waterproofing products provide the best possible protection against water and moisture damage.

- When it comes to waterproofing and protecting your surfaces, repairing cracks and gaps is essential. Before applying any waterproofing products, it is important to properly prepare the surface by filling in any cracks or gaps. This ensures that the waterproofing product adheres properly to the surface, providing maximum protection against water and moisture damage. Crack fillers are a type of repair material designed specifically for this purpose, offering a cost-effective and efficient way to address cracks and gaps in surfaces.

- Levelling compounds

- When it comes to repairing a damaged or uneven surface before waterproofing, levelling compounds can be a valuable tool in achieving a smooth and even surface. These materials are designed to fill in low spots and level out uneven areas, creating a surface that is ready for waterproofing. Levelling compounds are typically applied in a thin layer and can be used on a variety of substrates, including concrete, wood, and metal.

- However, it is important to note that proper surface preparation is crucial when using levelling compounds. The surface must be clean, dry, and free of debris before applying the compound. In some cases, primers or other preparatory coatings may also be necessary to ensure proper adhesion. Additionally, it is important to follow the manufacturer’s instructions for mixing and applying the compound to ensure optimal results. When used correctly, levelling compounds can help ensure a smooth and even surface for waterproofing, leading to a more effective and long-lasting waterproofing solution.

- When it comes to repairing a damaged or uneven surface before waterproofing, levelling compounds can be a valuable tool in achieving a smooth and even surface. These materials are designed to fill in low spots and level out uneven areas, creating a surface that is ready for waterproofing. Levelling compounds are typically applied in a thin layer and can be used on a variety of substrates, including concrete, wood, and metal.

- Primers

- Surface preparation is a critical step in any repair or waterproofing project. In addition to cleaning and removing surface contaminants, it is important to properly prime the surface to ensure proper adhesion of subsequent layers. Primers are specifically designed to penetrate and bond to the substrate, providing a strong and stable base for subsequent coatings or membranes.

- There are several types of primers available for different substrates, including concrete, metal, and wood. For example, a concrete primer may contain a blend of acrylics and epoxies to ensure proper adhesion to the porous surface of the concrete. On the other hand, a metal primer may contain rust inhibitors to prevent corrosion and ensure long-lasting adhesion. By properly selecting and applying the appropriate primer, you can improve the overall quality and durability of your repair or waterproofing project.

- Surface preparation is a critical step in any repair or waterproofing project. In addition to cleaning and removing surface contaminants, it is important to properly prime the surface to ensure proper adhesion of subsequent layers. Primers are specifically designed to penetrate and bond to the substrate, providing a strong and stable base for subsequent coatings or membranes.

- Crack fillers

- Cleaning Machines

Step-by-Step Surface Preparation Process for Waterproofing

Proper surface preparation is crucial for achieving a successful and long-lasting waterproofing project. Whether you are waterproofing a planter box, a roof, or a basement, following a step-by-step surface preparation process can ensure that the coating or membrane adheres properly to the substrate, eliminating surface contaminants and enhancing overall project quality. In this article, we will discuss the importance of surface preparation for waterproofing, and provide a step-by-step guide to help you achieve the best results

- Evaluate the surface condition: Before starting the surface preparation process for waterproofing, it is important to evaluate the surface condition of the substrate thoroughly. Check for any cracks, holes, or other defects that may compromise the integrity of the waterproofing layer. It is also important to ensure that the surface is clean and free of any contaminants such as oil, grease, or dirt. If necessary, use a pressure washer or other cleaning method to remove any debris and prepare the surface for further preparation.

- Select the appropriate preparation method: Once the surface has been evaluated, the next step is to select the appropriate preparation method based on the type of substrate and the extent of surface damage. Different methods such as shot blasting, scarification, or chemical cleaning may be used depending on the substrate condition. For example, shot blasting may be used for concrete surfaces while scarification may be used for asphalt surfaces. It is important to select the method that will provide the best adhesion for the waterproofing layer.

- Choose the right machines and materials: Selecting the right machines and materials is crucial to achieving a successful surface preparation. Consider factors such as the size and complexity of the project, the type of substrate, and the selected preparation method. For example, a large-scale project may require a more powerful machine while a smaller project may require a handheld tool. Additionally, select materials such as primers or leveling compounds that are compatible with the substrate and the waterproofing product.

- Prepare the work area: Properly preparing the work area is crucial for ensuring a safe and efficient surface preparation process. Clear the area of any debris or obstacles that may interfere with the preparation process. Make sure to also wear appropriate personal protective equipment such as gloves, safety glasses, and respiratory protection to protect against potential hazards such as dust or chemicals.

- Perform the surface preparation work: Once the work area is prepared, it is time to begin the surface preparation process. Follow the selected method and use the appropriate machines and materials to prepare the surface for waterproofing. Take care to ensure that the surface is properly prepared and free of any defects or contaminants.

- Inspect the prepared surface: After the surface preparation work is complete, inspect the prepared surface for any defects or inconsistencies. Check for any missed spots, cracks, or other damage that may require additional surface preparation. It is important to ensure that the surface is properly prepared before beginning the waterproofing process.

- Begin waterproofing: Once the surface preparation is complete and the surface has been inspected, it is time to begin the waterproofing process. Follow the manufacturer’s instructions and use the appropriate products and application techniques to achieve a long-lasting and effective waterproofing solution. Remember that proper surface preparation is crucial for ensuring the success of the waterproofing process and the durability of the substrate.

Conclusion

Proper surface preparation is crucial for the success of any waterproofing project. It ensures that the coating or membrane adheres properly to the substrate, eliminates surface contaminants, increases the lifespan of the coating or membrane, and enhances the overall project quality. Understanding the different types of surface preparation, methods, machines, and materials involved, and following a step-by-step process can help achieve the best results. By prioritizing surface preparation, you can ensure that your waterproofing project is a success and provides lasting protection to your building.

Various waterproofing works done by us:

- Grade Slab Waterproofing.

- Retaining Wall Waterproofing

- Podium Slab Waterproofing

- Swimming Pool Waterproofing

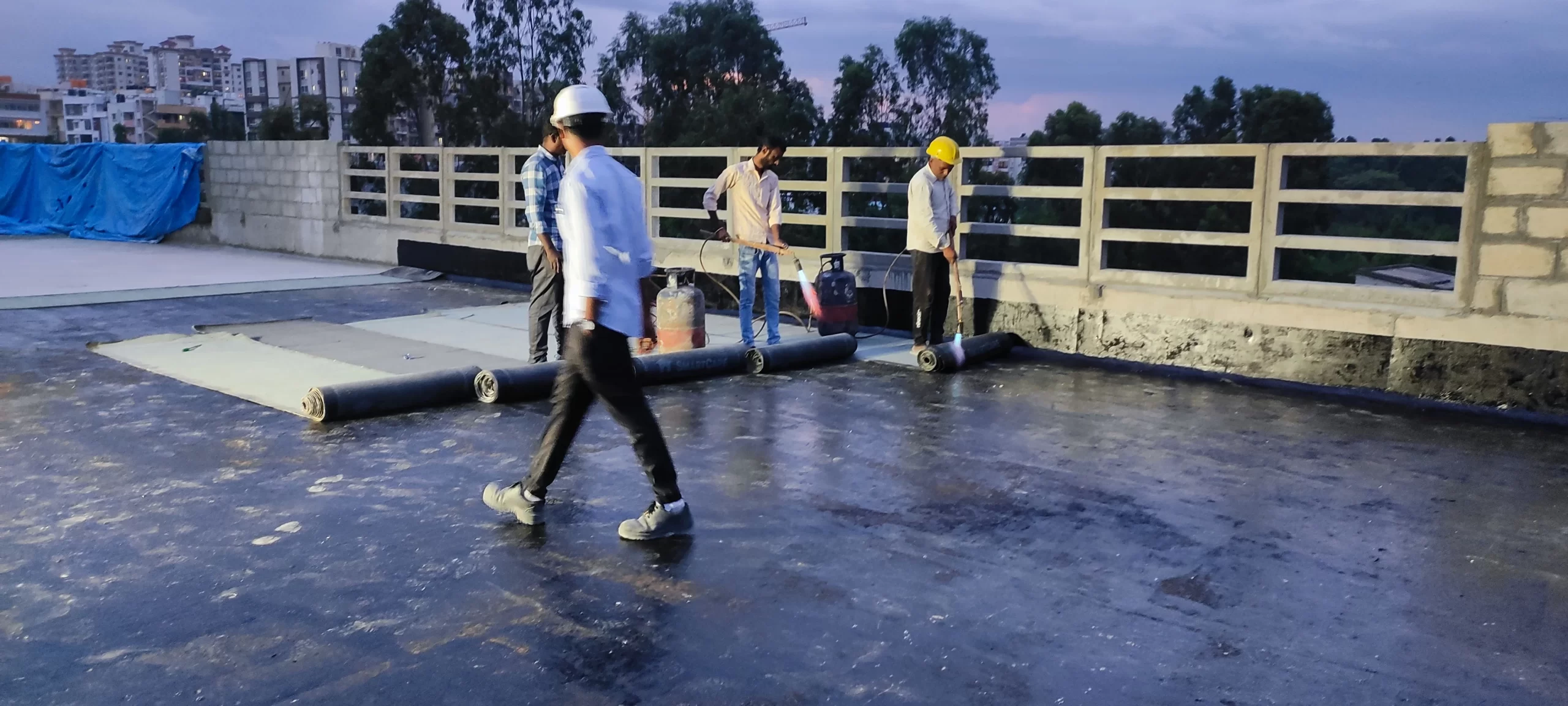

- Flat Roof Waterproofing

- Slope Roof Waterproofing

- Metal Roofs (Slope) Waterproofing

- Toilet Waterproofing

- Bathroom Waterproofing

- Wet Area Waterproofing

- Foundation Waterproofing

- Basement Waterproofing

- Balcony Waterproofing

- Underground Tanks Waterproofing

- Over Head Tanks Waterproofing

- Kitchen Waterproofing

- Sewage Treatment Plant (STP) Waterproofing

- Effluent treatment plant (ETP) Waterproofing

- Elevator Pit (Lift Pit) Waterproofing

- Roof Garden Waterproofing

- Construction Joint Waterproofing

- Planter Box Waterproofing

- Food grade coatings | Potable water tank Treatment

- Vertical Waterproofing – Building External Walls Waterproof painting

- Anti-Root system | Root Barrier

- Expansion Joint Waterproofing

- Tunnel Waterproofing

- Operation Theater Waterproofing

- Artificial Ponds Waterproofing

- Underground Vault Waterproofing

- Diaphragm Wall Waterproofing

- Multi Level Parking Decks (MLCP) Waterproofing

- Traffic Bearing Structure Waterproofing

GEOLIZ WATERPROOFERS PVT. LTD.

Waterproofing Products & Services Guide

For details on other waterproofing products & Services

Really enjoyed this piece on the importance of surface preparation for waterproofing. The detailed breakdown of methods and materials is super helpful, especially for those new to this. The step-by-step approach makes it easy to understand why each stage is critical for a successful waterproofing process. This kind of thorough and clear guidance is exactly what’s needed in the industry. Great job on covering such a crucial aspect of waterproofing!