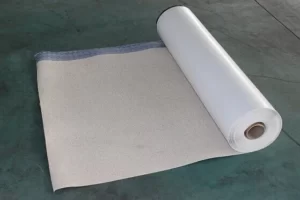

HDPE PRE APPLIED membrane with pressure sensitive adhesive layer

Description:

HDPE Pre Applied membrane (High Density Polyethylene) with a pressure-sensitive adhesive layer is a type of waterproofing material that is commonly used for below-grade waterproofing applications. This material is typically used in the construction of building foundations, retaining walls, and other structures where water infiltration could be a problem.

The HDPE Pre Applied membrane consists of a high-density polyethylene layer that is laminated with a pressure-sensitive adhesive layer. The adhesive layer is covered with a release liner that protects it until the membrane is installed. During installation, the release liner is peeled off, and the membrane is adhered to the surface that needs to be waterproofed.

The HDPE Pre-Applied Membrane with Pressure Sensitive Adhesive Layer is highly resistant to UV rays, chemicals, and punctures, making it a durable and reliable waterproofing solution. It is also designed to resist root penetration, making it suitable for use in green roofs and other vegetative applications.

HDPE Pre Applied membrane with pressure sensitive adhesive layer is a thick High density polyethylene membrane is a multi-layer compositive waterproofing material with superior performance, including a layer of high-performance PE film, self-adhesive polymer layer and a unique particulate layer. unlike conventional membranes, this forms a bond with the wet concrete poured over it and become monolithic part of the structure. This prevents water ingress tracking between the unbonded membrane and structure.

One of the key benefits of this HDPE Pre Applied membrane is that it can be installed quickly and easily. The pressure-sensitive adhesive layer eliminates the need for hot bitumen or torches, which can be dangerous and time-consuming.

Product Variants: HDPE Pre Applied membrane with Pressure Sensitive Adhesive Layer comes in various product variants, each with its own unique properties and specifications. For example, there may be variants with different thicknesses, widths, and lengths, surface particulate finishes, as well as different adhesive strengths and release liners.

Enhanced Building Envelope: By preventing water infiltration and air leakage, HDPE Pre Applied membrane with Pressure Sensitive Adhesive Layer can help to enhance the building envelope. This can improve indoor air quality, reduce energy costs, and extend the life of the building.

Cost-Effective: HDPE Pre Applied membrane with Pressure Sensitive Adhesive Layer is a cost-effective waterproofing solution. Its fast installation time, low maintenance requirements, and long service life can help to save money on construction and maintenance costs over the life of the building.

Uses of HDPE PRE APPLIED membrane with pressure sensitive adhesive layer:

- Basement: HDPE Pre Applied Waterproofing Membrane with Pressure Sensitive Adhesive Layer is an ideal solution for below-grade waterproofing of basement walls. The membrane’s durable, high-density polyethylene layer, laminated with a pressure-sensitive adhesive layer, provides excellent resistance to water and moisture. Its ability to withstand high hydrostatic pressures and its resistance to UV rays and other environmental factors make it a reliable and long-lasting solution for preventing water infiltration and damage to basement walls. The membrane is also easy to install, making it a cost-effective and efficient solution for below-grade waterproofing of basements.

- Subway and UG metro project: HDPE Pre Applied Waterproofing Membrane with Pressure Sensitive Adhesive Layer is an ideal solution for waterproofing subway and underground metro projects. The membrane’s high-density polyethylene layer, laminated with a pressure-sensitive adhesive layer, provides excellent resistance to water, moisture, and chemicals. Its ability to withstand high hydrostatic pressures and its durability make it a reliable and long-lasting solution for preventing water infiltration and damage to underground structures. The membrane can also be easily customized to fit any shape or size, making it a versatile solution for subway and metro projects. Additionally, its eco-friendliness and low maintenance requirements make it a cost-effective and sustainable solution for waterproofing underground structures.

- Cut and cover tunnels: HDPE Pre Applied Waterproofing Membrane with Pressure Sensitive Adhesive Layer is a unique and effective solution for waterproofing cut and cover tunnels. The membrane’s pressure-sensitive adhesive layer eliminates the need for hot bitumen or torches, making it a fast and easy installation process that can save time and money. Its high-density polyethylene layer provides excellent resistance to water and moisture, and its ability to withstand high hydrostatic pressures and resist root penetration makes it a reliable and long-lasting solution for waterproofing tunnels. The membrane’s customizable size and shape also make it an ideal choice for irregular tunnel shapes. Additionally, its low maintenance requirements and durability can help to reduce maintenance costs and extend the life of the tunnel. By using HDPE Pre-Applied Waterproofing Membrane with Pressure Sensitive Adhesive Layer, you can ensure the protection and integrity of cut and cover tunnels, even in harsh environments.

- Caverns: HDPE Pre-Applied Waterproofing Membrane with Pressure Sensitive Adhesive Layer is an excellent solution for waterproofing caverns due to its high-density polyethylene layer and pressure-sensitive adhesive layer, providing excellent resistance to water, moisture, and chemicals. Caverns have unique characteristics, including their size, shape, and depth, which require a specialized waterproofing solution that can be customized to fit their needs. The HDPE Pre-Applied Membrane is easily customizable and can be designed to cover complex and irregular surfaces. Additionally, the membrane’s heat fusion seams provide exceptional seam strength, which is crucial in caverns to prevent water infiltration and the resulting structural damage. The membrane’s eco-friendliness and low maintenance requirements also make it a sustainable solution for waterproofing caverns. By using HDPE Pre-Applied Waterproofing Membrane with Pressure Sensitive Adhesive Layer, the integrity of the cavern structure can be protected, ensuring its longevity and reducing the risk of environmental damage.

- Other underground civil structures.

APPLICATION INSTRUCTIONS for HDPE PRE APPLIED membrane with pressure sensitive adhesive layer

Pre Applied HDPE with pressure sensitive adhesive layer membranes are supplied in rolls of 2.0 m or 2.4 m wide, with a selvedge of 75 mm on one side to provide self-adhered laps for continuity between rolls. The rolls of membrane and Pre applied Tape are inter-wound with a disposable plastic release liner which must be removed before placing reinforcement and concrete.

Details regarding the installation shall be shared on contacting with us.

GEOLIZ WATERPROOFERS PVT. LTD.

Waterproofing Products & Services Guide

For details on other waterproofing products & Services