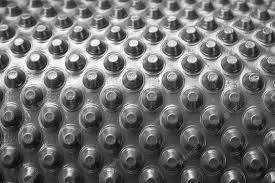

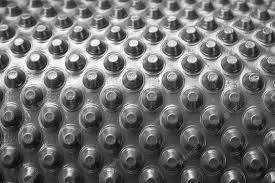

Black HDPE Dimple Protection and Drainage Board, For Industrial, DIMPLE THICKNESS: 8mm

Waterproofing is an important aspect of construction and is crucial for protecting buildings and structures from water damage. One of the essential components of waterproofing systems is the HDPE dimple protection board. This board is a versatile and reliable product that offers a range of benefits for waterproofing applications. In this article, we will explore the various uses and advantages of the HDPE dimple protection board and provide technical details and insights about the product.

Price Details:

| Description | Details |

|---|---|

| Dimple Protection Board | Rs. 125 – Rs. 150 / SQM |

| GST (18%) | According to slab |

| Transportation | Extra |

| HSN Code | 3920 |

Note: Prices are subject to change without prior notice. Please contact us for a customized quote based on your specific requirements.

Description: What are HDPE Dimple Protection Boards?

The HDPE dimple protection board is a type of high-density polyethylene (HDPE) sheet with a dimpled surface. It is typically used as a protective layer for waterproofing membranes against physical damage, water penetration, and other external factors that can compromise the waterproofing system’s effectiveness. The dimples provide a channel for water drainage, which helps to prevent the accumulation of water on the surface.

Uses of HDPE Dimple Protection Board

The HDPE dimple protection board has numerous applications across a range of industries, including construction, civil engineering, and infrastructure development. Some of the common uses of the product include:

Protection of Waterproofing Membranes

One of the primary uses of the HDPE dimple protection board is to protect waterproofing membranes from physical damage caused by external factors such as soil pressure, foot traffic, and heavy equipment. The board provides a layer of insulation between the membrane and the external environment, preventing the membrane from tearing or puncturing.

Drainage of Ground Water

The HDPE dimple protection board can also be used to drain ground water away from the structure. The dimpled surface provides a channel for water to flow, which helps to prevent water from accumulating around the foundation or basement walls. This is especially useful in areas with high water tables or heavy rainfall.

HDPE Dimple Protection Board as a Backing for Retaining Wall Waterproofing Membrane

The HDPE Dimple Protection Board can be used as a backing for the installation of retaining wall waterproofing membranes over temporary soil retention systems such as shotcrete and piles. The dimple board is installed over the plain shotcrete surface to create a level surface, and the waterproofing membrane is then fixed to the dimple protection board. This is particularly useful in confined space construction of retaining walls, where single-side shuttering is required. By using the HDPE Dimple Protection Board, the waterproofing membrane is protected from potential damage caused by soil pressure, while also providing an efficient drainage layer.

Moisture Barrier for Concrete

The HDPE dimple protection board can be used as a moisture barrier for concrete structures. It helps to prevent moisture from seeping into the concrete, which can cause it to deteriorate over time. This is particularly important in structures like basements, parking lots or bridges, where exposure to moisture can be high.

Clean Surface for Base Instead of Lean Concrete

In some cases, the HDPE dimple protection board is used as an alternative to lean concrete for creating a clean surface on the base. It is laid on the soil to create a smooth and level surface, which can then be used as a base for further construction. This is useful in areas where lean concrete is difficult to install or where a clean surface is necessary.

Protection of Underground Waterproofing System against Soil Pressure

The HDPE dimple protection board also protects the underground waterproofing system from soil pressure. The board provides a buffer between the soil and the waterproofing membrane, reducing the impact of soil pressure on the membrane.

Drainage in Tunnels

The HDPE dimple protection board can also be used in tunnels to enable the transmission of intense water to the drainage channels. It helps to prevent water from accumulating in the tunnel, which can cause damage to the structure or impact the flow of traffic.

Other Uses

The HDPE dimple protection board can also be used in a variety of other applications, including basement walls, metro/train tunnels, highways, parking areas, dams, pipelines, roads, and terrace gardens.

Advantages of HDPE Dimple Protection Board

The HDPE dimple protection board is an extremely robust and versatile product that offers a range of benefits.

Chemical Resistance

One of its most significant advantages is its excellent chemical resistance, which makes it highly resistant to acids, alkalis, and other solvents. This chemical resistance ensures that the product can be used in a range of applications without the risk of damage or deterioration.

The chemical resistance of the HDPE dimple protection board is due to its high-density polyethylene material, which is inherently resistant to a wide range of chemicals. This material is highly durable and provides an effective barrier against aggressive substances that may cause damage to other materials. As a result, the HDPE dimple protection board is often used in applications where exposure to chemicals is likely, such as in industrial plants, chemical storage facilities, and other similar environments.

resist the roots of plants

HDPE Dimple Protection Board is designed to resist the roots of plants, which can cause damage to waterproofing systems over time. The board provides an impermeable barrier to plant roots, preventing them from penetrating through to the underlying waterproofing system. This is achieved through the use of a high-density polyethylene material that is resistant to plant root growth.

The use of HDPE Dimple Protection Board provides an effective solution to prevent root intrusion and damage to waterproofing systems. The product has been tested extensively for plant root growth resistance and has been found to perform exceptionally well in preventing root penetration.

Non-Toxic and Non-Polluting:

Another advantage of HDPE dimple protection board is that it is non-toxic and non-polluting. This makes it a safe and eco-friendly option for various applications, especially for projects that involve water storage or management. Being non-toxic, it poses no health risks to humans or animals. Additionally, it is non-polluting, which means that it does not release harmful substances into the environment. This makes it an ideal choice for sustainable construction practices.

Furthermore, the non-toxic and non-polluting nature of HDPE dimple protection board ensures that it does not affect the quality of water that comes into contact with it. This makes it suitable for use in applications where water is stored or managed, such as dams, reservoirs, and drainage systems. With this feature, HDPE dimple protection board ensures that water is kept clean and free from harmful chemicals. This makes it a reliable and effective solution for various waterproofing and water management applications.

Improves Breathability:

One of the advantages of using HDPE dimple protection board is that it helps improve breathability. The dimpled structure of the board creates a void space between the membrane and the soil or concrete substrate, allowing air to circulate and moisture to evaporate. This helps prevent moisture buildup, which can lead to the growth of mold, mildew, and other fungi that can compromise the integrity of the structure. By allowing air to circulate, the board also helps regulate temperature and reduce the risk of condensation, which can cause moisture-related damage to the structure over time.

Additionally, the dimple structure of the board creates a drainage space that helps channel water away from the membrane and prevent standing water from accumulating. This is particularly important in areas where heavy rainfall is common or where the water table is high. By improving drainage and preventing water from accumulating, the board helps protect the membrane and the underlying structure from water-related damage.

Durable and Long-Lasting:

HDPE dimple protection board is known for its durability and long-lasting performance. Due to its high-density polyethylene composition, it can withstand heavy loads and high pressure, making it ideal for applications such as protection of waterproofing membranes against physical damage and protection of the underground waterproofing system against damages caused by soil pressure.

Additionally, the board has excellent resistance to environmental factors such as weather, moisture, and UV radiation, which can cause degradation and weakening of other materials over time. Its resistance to plant roots further adds to its longevity, as it prevents damage from root penetration. With its superior durability and long-lasting performance, the HDPE dimple protection board provides a cost-effective solution for various construction and waterproofing needs.

Superior Protection:

HDPE dimple protection board is easy to install due to its lightweight and flexible nature. The boards are available in large sheets, which can be easily cut to size with a sharp knife or scissors. They can be quickly and easily laid onto the surface without any special tools or adhesives. The boards can be attached to the wall with profiles or laid directly onto the ground with overlaps, which are then fixed to each other by hot air hand welding or glued insulated tape.

The simplicity of installation makes the HDPE dimple protection board an ideal choice for contractors and builders who need to complete projects quickly and efficiently. The boards can be installed with minimal effort and do not require any specialized training or equipment. Additionally, the easy installation process can help reduce the overall cost of a project, saving time and money.

PHYSICAL AND MECHANICAL PROPERTIES OF 8mm DIMPLE PROTECTION BOARD

| CHARACTERISTICS | STANDARDS | MEASURING UNIT | TOLERANCES | VALUES |

|---|---|---|---|---|

| Total Weight | EN 9864 | g/m2 | ±5% | 400 |

| Dimple Height | EN 9863-1 | mm | ±10% | 8 |

| Compression Strength | kN/m2 | ±20% | 150 | |

| Short Width Tensile Strength MD/CMD | EN 12311-2 | N/50mm | > 200/200 | |

| Elongation At Max Load MD/CMD | EN 12311-2 | % | – | > 20 / 25 |

| Air Gap Volume Between Dimples | – | l/m2 | -20% | 5 |

| Temperature Range | 0C | -30 to 80 | ||

| Drain Flow Capacity In Plane | EN 12958 | L/m2/s | -20% | 2.25 |

| Flow Rate | EN 12958 | L/min./m | -20% | 200 |

| Reaction To Fire | — | — | — | Class ‘E’ |

| Resistance To Water Penetration | — | — | — | Waterproof (W1) |

| PACKAGE DIMENSIONS | ||||

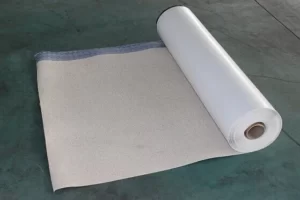

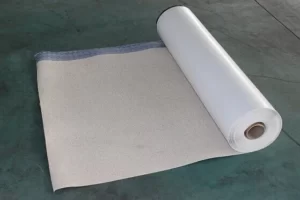

| Roll width | m | ±3% | 2.3 | |

| Roll length | m | ±2% | 20 |

APPLICATION INSTRUCTIONS

Installation of HDPE Dimple Protection Board is an important step in ensuring effective waterproofing and soil retention. Follow these steps for proper installation:

- Prepare the surface: Clean the surface where the Dimple Protection Board will be installed to ensure it is smooth, clean, and free of protrusions or sharp objects that may damage the board.

- Unroll the board: Roll out the Dimple Protection Board onto the prepared surface, making sure it is aligned and centered correctly.

- Cut and trim: Use a sharp knife or scissors to cut the board to the required size and shape, taking care to make precise cuts and avoid any damage to the board.

- Overlap the boards: For larger areas, overlap multiple boards by at least 100 mm and use a hot air gun to weld the seams together.

- Fix the board: Fix the board to the surface using mechanical fixings or adhesive, following the manufacturer’s instructions.

- Install the waterproofing membrane: Once the Dimple Protection Board is installed, install the waterproofing membrane on top of it using the appropriate adhesive or mechanical fixings.

- Test the system: Test the system thoroughly to ensure it functions correctly and provides the required level of protection.

In vertical applications, fix the HDPE Dimple Protection Board to the wall with profiles in the subbasement level. Ensure the direction of the dimples is towards the outer side of the wall. Overlap the joints between the plates by at least 20 cm. Fix the overlap parts of the plates to each other by hot air hand welding or glued insulated tape if desired.

In horizontal applications, lay the HDPE Dimple Protection Board on the ground. Ensure the direction of the dimples is towards the ground. Overlap the joints between the plates by at least 30 cm. Fix the overlap parts of the plates to each other by hot air hand welding or glued insulated tape if desired.

The ideal application temperature range for HDPE Dimple Protection Board is between +5 to +30 degrees Celsius. Always refer to the manufacturer’s instructions for specific installation guidelines and recommended best practices.

Looking for high-quality HDPE Dimple Protection Board for your next project? Look no further than Geoliz Waterproofers Pvt. Ltd., your trusted dealer for this top-of-the-line product in Bangalore. Contact us today to place your order and ensure the best possible protection for your building’s foundation.

GEOLIZ WATERPROOFERS PVT. LTD.

Waterproofing Products & Services Guide

For details on other waterproofing products & Services