1.Crystalline Waterproofing Slurry Coating

Description:

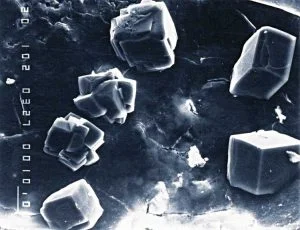

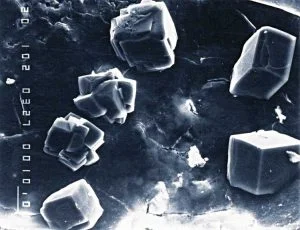

A crystalline coating is a type of waterproofing system that uses a unique technology to improve the durability and waterproofing properties of concrete surfaces. The crystalline coating is based on the principle of crystallization, which involves the growth of microscopic crystals within the pores and capillaries of the concrete surface.

Crystalline Waterproofing Slurry Coating are typically composed of a blend of cementitious materials, specialized chemicals, and other additives that work together to create a dense and impermeable layer on the concrete surface. The coating is designed to penetrate deeply into the concrete and fill any pores or capillaries, creating a highly durable and waterproof surface.

The Crystalline Waterproofing Slurry Coating is typically applied as a slurry or spray, and may require multiple coats to achieve the desired level of coverage and performance. As the coating dries and cures, microscopic crystals begin to form within the concrete, creating a highly dense and impermeable layer.

Crystalline Waterproofing Slurry Coating are commonly used in a variety of applications, including basement waterproofing, foundation repair, and concrete protection. They are highly effective at preventing water infiltration and improving the durability of concrete surfaces, making them a popular choice for both residential and commercial applications.

Crystalline Waterproofing Slurry Coating are also known for their ability to self-seal any hairline cracks that may occur in the concrete surface over time. This helps to maintain the integrity of the coating and extend its lifespan, while also reducing the need for ongoing maintenance and repairs.

Uses:

Can be applied to all structurally sound old and new concrete .

Basement, retaining wall, concrete slabs

Water retaining structures, swimming pools, sewage treatment plants, bridges .

Concrete water tanks, lifts well, inspection pits.

Foundation, dams, tunnels and underground and marine structures.

Application Instructions:

The application instructions for Crystalline Waterproofing Slurry Coating may vary depending on the specific product and manufacturer. However, here are some general guidelines for applying crystalline coatings:

- Surface Preparation: The surface to be coated must be clean, dry, and free of any contaminants such as oil, grease, dirt, and loose particles. Any cracks or defects should be repaired and filled as needed.

- Mixing: The crystalline coating should be mixed according to the manufacturer’s instructions. This involve adding water to the powder and mixing until a uniform consistency is achieved in the proportions recommended by the manufacturer.

- Application: The coating may be applied using a stiff brush or spray gun, depending on the specific product and application method. The coating should be applied evenly and at the recommended thickness/density to ensure proper coverage and performance.

- Curing: After the coating has been applied, it should be allowed to cure for the recommended time before being exposed to water or other liquids. The curing time may vary depending on the specific product and environmental conditions.

- Covering: Depending on the specific product and application, a Cement mortar plaster may be applied to the surface to further enhance its performance and appearance.

It is important to follow the manufacturer’s instructions carefully when applying crystalline coatings to ensure a proper seal and optimal performance. Additionally, proper safety precautions should be taken, such as wearing protective clothing, gloves, and eye protection, and ensuring adequate ventilation during the application process.

COVERAGE

Concrete surface to be backfilled : One coat of Crystalline coating @ 0.75 kg/m2. followed by another coat of Crystalline coating @ 1 kg/m2.

Water retaining structures: Internal concrete wall surface: Two coats of Crystalline coating @ 0.75kg/m2 brush apply.

Concrete Slabs: Crystalline coating@ 1.8kg/m2 applied as slurry coat to hardened concrete or dry sprinkle and trowel on fresh concrete when it starts setting.

Construction Joints: Crystalline coating @1.2kg/m2 as slurry / powder immediately prior to placing the next bay of concrete.

Blinding Concrete : Crystalline coating@ 1.2kg/m2 applied in slurry / powder immediately prior to placing the overlaying concrete slab.

Related Posts:

GEOLIZ WATERPROOFERS PVT. LTD.

Waterproofing Products & Services Guide

For details on other waterproofing products & Services